Material

Double wedge and clamping segments mild steel.

Version

Double wedge and clamping segments hardened, phosphated.

Show more

Show less

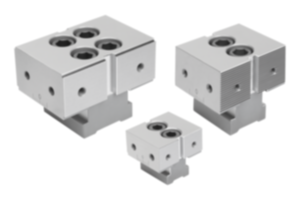

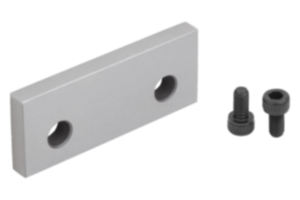

Wedge clamps, Form A, smooth jaw face

from

€136.50

plus sales tax

plus shipping costs

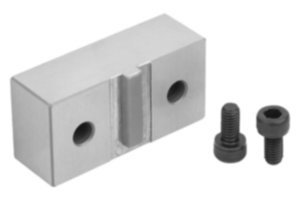

Wedge clamps, Form B, jaw face serrated

from

€173.25

plus sales tax

plus shipping costs

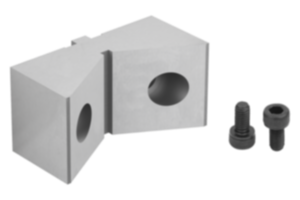

Wedge clamps, Form C, with step

from

€178.50

plus sales tax

plus shipping costs

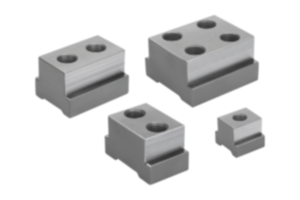

Wedge clamps, Form D, with machining allowance

from

€141.75

plus sales tax

plus shipping costs

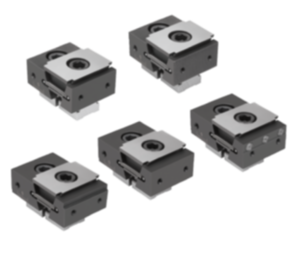

Wedge clamps, Form E, with jaw pins

from

€205.00

plus sales tax

plus shipping costs

Description

Product description

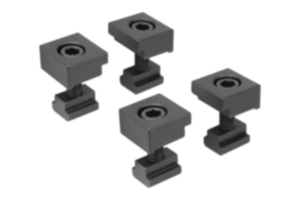

The functioning principle make the wedge clamps ideal for multi-clamping.

The wedge shape creates high clamping forces.

The wedge clamps can be used for clamping in conjunction with the clamping rail or mounted in tapped holes or T-slots.

Tightening the clamping screw moves the two clamping segments outwards and press the workpieces against the fixed jaws of the machining fixture.

The double wedge has an elongated hole allowing for movement and to compensate for tolerances.

Displacement: M12 = ±1 mm, M16 = ±1.5 mm.

The wedge shape creates high clamping forces.

The wedge clamps can be used for clamping in conjunction with the clamping rail or mounted in tapped holes or T-slots.

Tightening the clamping screw moves the two clamping segments outwards and press the workpieces against the fixed jaws of the machining fixture.

The double wedge has an elongated hole allowing for movement and to compensate for tolerances.

Displacement: M12 = ±1 mm, M16 = ±1.5 mm.

Material

Double wedge and clamping segments mild steel.

Version

Double wedge and clamping segments hardened, phosphated.

Note

The two screw-on holes in the clamping faces also enable seating ledges to be mounted so as to optimise the clamping depth of the workpieces.

Scope of delivery

Wedge clamps.

Fastening screw.

Fastening screw.

Drawing reference

Form A: Smooth jaw face

Form B: Serrated jaw facet

Form C: With step

Form D: With machining allowance

Form E: With jaw pins

Form B: Serrated jaw facet

Form C: With step

Form D: With machining allowance

Form E: With jaw pins