Material

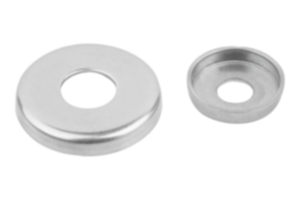

Knife edge washer.

Cam screw carbon steel.

Cam screw carbon steel.

Version

Cam screw tempered to 10.9 and black oxidised.

Knife edge washer hardened and anodised.

Knife edge washer hardened and anodised.

Show more

Show less

Description

Material

Knife edge washer.

Cam screw carbon steel.

Cam screw carbon steel.

Version

Cam screw tempered to 10.9 and black oxidised.

Knife edge washer hardened and anodised.

Knife edge washer hardened and anodised.

Note

The hardened knife edge washer is suitable for clamping rough pieces (saw cut stock, castings, forgings etc).

Not designed for clamping hardened materials with the torque specified.

Clockwise rotation is recommended for clamping. The hex socket on the screw should be on the right after tightening. (Screw in the cam screw as far as it will go, then turn it back one turn).

”A” = distance from workpiece to screw centre (cam screw).

Not designed for clamping hardened materials with the torque specified.

Clockwise rotation is recommended for clamping. The hex socket on the screw should be on the right after tightening. (Screw in the cam screw as far as it will go, then turn it back one turn).

”A” = distance from workpiece to screw centre (cam screw).

On request

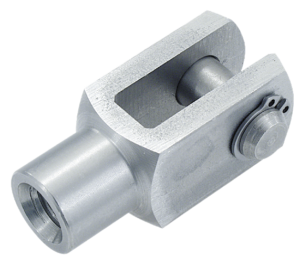

Replacement screw for cam screws K1969

Clamping force

Cam screws with knife edge washer

Function principle

Clamping method:

1. Screw the cam screw in as far as it will go.

2. Screw the cam screw back one turn.

3. Position the workpiece.

4. Turn the cam screw clockwise to clamp the workpiece.

(The hex socket on the cam screw should now be on the right).

1. Screw the cam screw in as far as it will go.

2. Screw the cam screw back one turn.

3. Position the workpiece.

4. Turn the cam screw clockwise to clamp the workpiece.

(The hex socket on the cam screw should now be on the right).

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.