Material

Steel version:

Threaded sleeve and indexing pin free-cutting steel.

Spring 1.4310.

Stainless steel version A2:

Threaded sleeve 1.4305.

Hardened indexing pin 1.4034.

Not hardened indexing pin 1.4305.

Spring 1.4310.

Stainless steel version A4:

Threaded sleeve and indexing pin 1.4404.

Spring 1.4401 or 1.4571.

Mushroom grip thermoplastic, dark grey or traffic red RAL3020.

Version

Steel version:

Threaded sleeve, black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel A2 version:

threaded sleeve bright.

Indexing pin hardened or not hardened, ground and bright.

Stainless steel A4 version:

threaded sleeve bright.

Indexing pin ground, chemically nickel-plated or bright.

Threaded sleeve, black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel A2 version:

threaded sleeve bright.

Indexing pin hardened or not hardened, ground and bright.

Stainless steel A4 version:

threaded sleeve bright.

Indexing pin ground, chemically nickel-plated or bright.

Show more

Show less

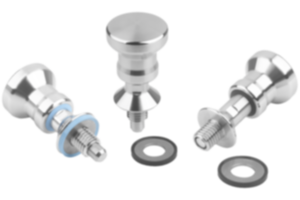

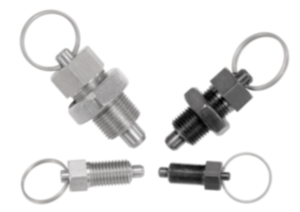

Indexing plungers, Form A

from

7,24 €

plus sales tax

plus shipping costs

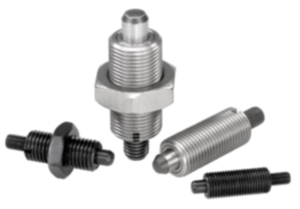

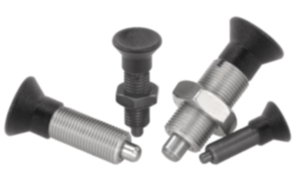

Indexing plungers, Form B

from

7,36 €

plus sales tax

plus shipping costs

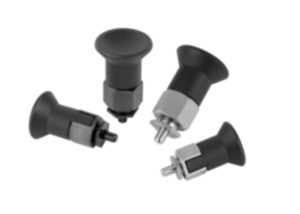

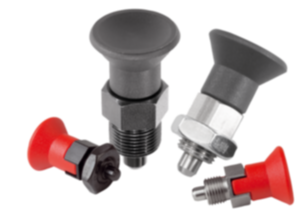

Indexing plungers, Form C

from

9,08 €

plus sales tax

plus shipping costs

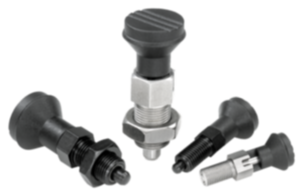

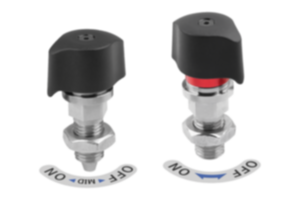

Indexing plungers, steel or stainless steel with plastic mushroom grip, locking slot and locknut

from

9,19 €

plus sales tax

plus shipping costs

Description

Product description

Indexing plungers are used where it is necessary to prevent changes of position due to lateral forces.

Some examples of this are for length, height and position indexing in machines, equipment, furniture and special vehicle construction.

A new indexed position can be only be moved to after the pin has been manually retracted. Form C and D are recommended for applications where the indexing pin should remain disengaged for an extended period and be prevented from springing back.

The materials used enable a wide range of applications.

Indexing plungers made from A4 stainless steel are recommended for applications with very high corrosion resistance requirements.

Some examples of this are for length, height and position indexing in machines, equipment, furniture and special vehicle construction.

A new indexed position can be only be moved to after the pin has been manually retracted. Form C and D are recommended for applications where the indexing pin should remain disengaged for an extended period and be prevented from springing back.

The materials used enable a wide range of applications.

Indexing plungers made from A4 stainless steel are recommended for applications with very high corrosion resistance requirements.

Material

Steel version:

Threaded sleeve and indexing pin free-cutting steel.

Spring 1.4310.

Stainless steel version A2:

Threaded sleeve 1.4305.

Hardened indexing pin 1.4034.

Not hardened indexing pin 1.4305.

Spring 1.4310.

Stainless steel version A4:

Threaded sleeve and indexing pin 1.4404.

Spring 1.4401 or 1.4571.

Mushroom grip thermoplastic, dark grey or traffic red RAL3020.

Version

Steel version:

Threaded sleeve, black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel A2 version:

threaded sleeve bright.

Indexing pin hardened or not hardened, ground and bright.

Stainless steel A4 version:

threaded sleeve bright.

Indexing pin ground, chemically nickel-plated or bright.

Threaded sleeve, black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel A2 version:

threaded sleeve bright.

Indexing pin hardened or not hardened, ground and bright.

Stainless steel A4 version:

threaded sleeve bright.

Indexing pin ground, chemically nickel-plated or bright.

On request

Special versions.

Drawing reference

Form A: non-lockout type, without locknut

Form B: non-lockout type, with locknut

Form C: lockout type, without locknut

Form D: lockout type, with locknut

Form B: non-lockout type, with locknut

Form C: lockout type, without locknut

Form D: lockout type, with locknut