Height adjustment elements

Height adjustment elements are intended for use in levelling and mounting motors, aggregates, drive units and assembly lines.

Les éléments de compensation KIPP

Les éléments de compensation sont des éléments de manœuvre servant à compenser des irrégularités, des défauts angulaires et des tolérances. Ils contribuent à ce que les composants puissent être reliés entre eux de manière sûre et stable. Ces éléments de manœuvre font partie des composants indispensables dans l’industrie mécanique et manufacturière. Ils aident à maintenir des réglages précis et des alignements optimaux des machines et des structures. Les éléments de compensation courants permettent une adaptation flexible dans différents domaines d’application. Il s’agit notamment des rondelles convexes et concaves, des rondelles de compensation à rotule et des vérins de nivellement. Les éléments de compensation favorisent la longévité et l’efficacité de l’ensemble de la structure. Les éléments de compensation assurent une répartition uniforme des charges, en particulier dans les secteurs industriels exigeants où la plus grande précision est requise. Ils constituent donc un élément clé de la technologie de fabrication moderne. |

Types d’éléments de compensation

Rondelles convexes et concaves

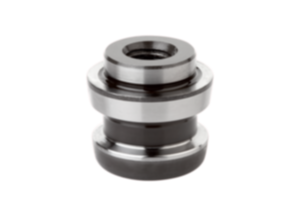

Rondelles de compensation à rotule

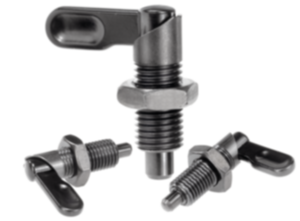

Vérins de nivellement

Avantages et critères de choix principaux des éléments de compensation

KIPP, votre spécialiste des éléments de positionnement

Types d’éléments de compensation

Les éléments de compensation sont des composants mécaniques utilisés pour compenser les tolérances dans les machines et les structures. Ces différents éléments permettent une adaptation et un alignement flexibles. On les trouve dans la construction mécanique ainsi que dans les constructions et les processus de fabrication.

Les éléments de compensation permettent une adaptation flexible à diverses conditions. Ces éléments de manœuvre apportent ainsi stabilité, durabilité et sécurité à la structure.

KIPP les propose dans les matériaux robustes suivants :

- l’inox

- l’inox A2

- l’acier de cémentation

- l’acier

- l’acier de traitement

Rondelles convexes et concaves

Une rondelle convexe est constituée d’une rondelle à la surface sphérique. Celle-ci sert à compenser les écarts angulaires dans les assemblages vissés ou entre les composants. Les rondelles convexes permettent une répartition uniforme de la charge, même en cas de surfaces de contact inclinées, évitant ainsi les tensions dans l’assemblage.

Ces éléments de positionnement spéciaux sont utilisés dans l’ingénierie et la construction mécanique. Ils permettent de compenser les défauts d’inclinaison ou d’angle entre les composants.

Les rondelles convexes sont surtout utilisées pour les assemblages vissés qui nécessitent un ajustement précis. L’adaptation permet de réduire les contraintes et d’accroître la longévité de ces assemblages. Les rondelles convexes sont utilisées dans les applications où les composants ne sont pas complètement alignés en raison des tolérances de fabrication, de la déformation ou de la dilatation thermique, ce qui nécessite une réduction des contraintes ou une compensation de la hauteur.

Les rondelles KIPP sont en acier ou en inox 1.4301. Elles sont fabriquées en acier cémenté avec une profondeur de trempe d’au moins 0,2 mm.

Nos rondelles convexes sont souvent utilisées en association avec d’autres éléments de manœuvre, notamment avec la rondelle concave. Ces deux composants forment une unité solidaire et imperdable, ce qui permet un montage rapide et facile.

Les rondelles concaves, souvent aussi appelées coques de serrage, sont des rondelles de forme concave qui assurent une fixation ferme des composants. Elles sont utilisées comme éléments de compensation en association avec des rondelles convexes. Ces éléments de manœuvre possèdent une cavité conique (coque) dans laquelle vient s’insérer la rondelle convexe. Elles permettent ainsi un ajustement angulaire précis entre les composants reliés.

Les modèles favoris de nos clients :

- Rondelles convexes, rondelles concaves DIN 6319, version 10/01

- Rondelles convexes et rondelles concaves combinées en acier ou en inox, similaires à la norme DIN 6319

Rondelles de compensation à rotule

Les rondelles de compensation à billes sont également connues sous le nom de rondelles de butée à billes. Elles sont utilisées pour une transmission optimale des forces entre des surfaces non parallèles ou irrégulières. Elles sont également utilisées pour compenser des différences de hauteur et des écarts angulaires.

Les rondelles de compensation à billes sont composées de deux rondelles, l’une concave (bombée vers l’intérieur) et l’autre convexe (bombée vers l’extérieur). Grâce à leur forme, les rondelles de compensation à billes empêchent la formation de tensions ou de pressions sur les bords lorsque les composants sont inclinés les uns par rapport aux autres. |

Les principales caractéristiques et applications des rondelles de compensation à billes sont les suivantes :

- La compensation angulaire : Compensation des petits écarts angulaires entre les surfaces.

- Réduction de la tension : Empêchent la tension excessive et la pression sur les bords.

- Domaines d’application : Souvent utilisées dans les assemblages à vis et à boulons, en particulier dans les structures soumises à des forces élevées, comme dans la construction mécanique et la construction métallique.

Les rondelles de compensation à billes KIPP permettent un appui précis lors du montage sur des surfaces inclinées avec un angle d’inclinaison pouvant atteindre 4°. Elles sont disponibles en deux versions de matériaux :

- en acier 1.7225, passivé bleu

- en inox 1.4305, brut

Vérins de nivellement

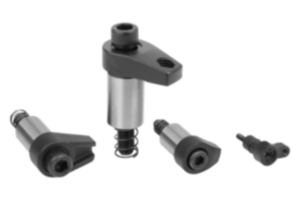

Les vérins de nivellement sont des composants utilisés dans diverses applications techniques. Ces éléments de manœuvre permettent d’adapter avec précision la hauteur ou la position du composant. Ils permettent par ailleurs d’aligner et d’installer des moteurs, des groupes moteurs, des éléments de motorisation et des lignes de production.

Les vérins de nivellement sont composés d’un mécanisme réglable, comme un filetage ou une broche. Celui-ci permet une adaptation flexible à différentes hauteurs de montage ou niveaux.

Ces éléments sont utilisés dans la construction de machines et d’installations, où ils servent au réglage fin, au nivellement et à l’adaptation aux surfaces irrégulières.

Les vérins de nivellement KIPP offrent une course de réglage importante de 15 à 40 mm. D’autres tailles sont disponibles sur demande.

Outre un modèle standard, la gamme KIPP comprend également les vérins de nivellement suivants :

- avec contre-écrou

- modèle bas

- avec rondelle de compensation à billes

- avec rondelle de compensation à billes et contre-écrou

Avantages et critères de choix principaux des éléments de compensation

Nos éléments de compensation offrent une multitude d’avantages qui les rendent indispensables dans de nombreuses applications techniques. Ils permettent de compenser les défauts d’inclinaison et d’angle entre les composants, ce qui réduit les contraintes sur les assemblages. Cela permet de protéger le matériau contre les tensions qui peuvent survenir en raison des tolérances et de la déformation.

Ces éléments permettent également un alignement simple et précis des composants, de sorte qu’une adaptation flexible est possible rapidement. La répartition uniforme des forces assure une liaison stable et améliore les performances de l’ensemble de la structure. En minimisant les pics de charge, nos éléments de compensation contribuent à prolonger la durée de vie des éléments de liaison tels que les vis et autres fixations.

Le montage est considérablement simplifié grâce à l’utilisation de nos rondelles convexes et concaves qui s’installent facilement et rapidement, ce qui permet d’économiser du temps et des efforts. De plus, nos vérins de nivellement offrent une plage de réglage généreuse de 15 à 40 mm, ce qui permet une grande flexibilité dans différentes applications.

Sur demande, KIPP propose également des tailles spéciales qui garantissent une adaptation optimale à des exigences spécifiques.

Dans l’ensemble, nos éléments de compensation contribuent considérablement à l’efficacité et à la stabilité dans diverses applications techniques.

Lors du choix des éléments de compensation, les critères suivants doivent être pris en compte :

- la qualité du matériau

- la capacité de charge

- la portance

- la facilité de montage

- la compatibilité avec les systèmes existants

KIPP, votre spécialiste des éléments de positionnement

KIPP est votre spécialiste des éléments de positionnement qui permettent un alignement et un ajustement précis dans les applications techniques. Grâce à notre large gamme de produits de qualité, nous proposons des solutions parfaitement adaptées à vos exigences particulières.

Nos éléments de compensation se caractérisent par leur facilité d’utilisation, leur grande flexibilité et leurs performances fiables. Que ce soit pour l’industrie mécanique, les installations de fabrication ou les applications spéciales, KIPP vous offre une qualité et une fonctionnalité maximales.